Fret Caul Alignment & Even Pressure

- Gary Carter

- Aug 8, 2025

- 2 min read

Updated: 6 days ago

KINEMATIC DESIGN

Our luthier tool designs are grounded in the principles of kinematics & mechanics.

BASIC PRESS METHODOLOGY

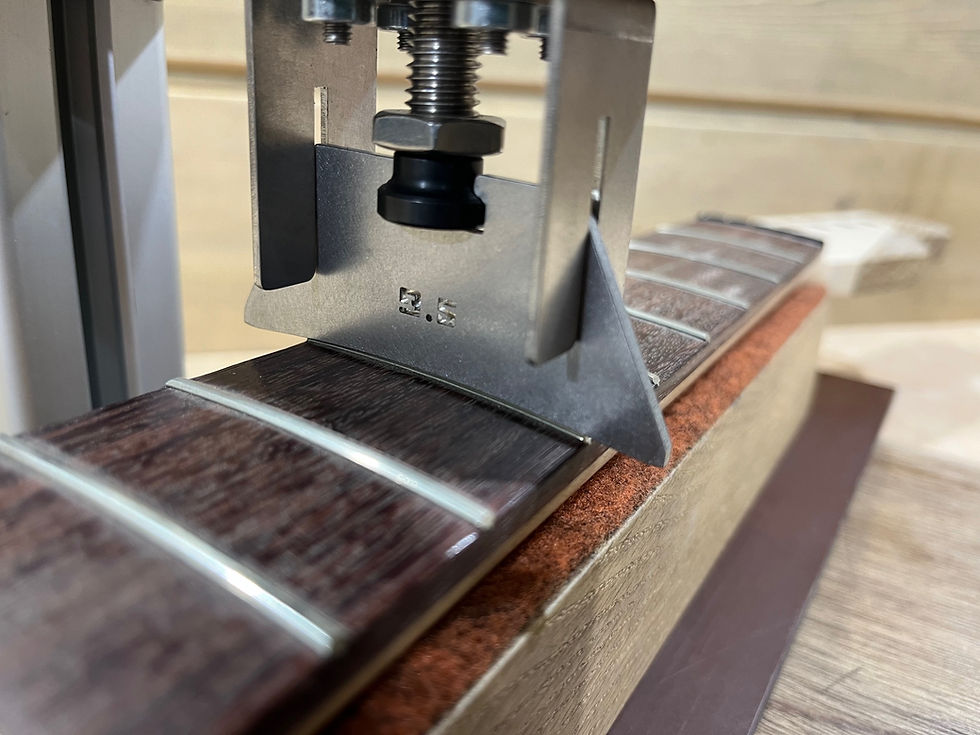

1) Pre-Bent Fret :- Tang constrained within the radiused fretboard slot.

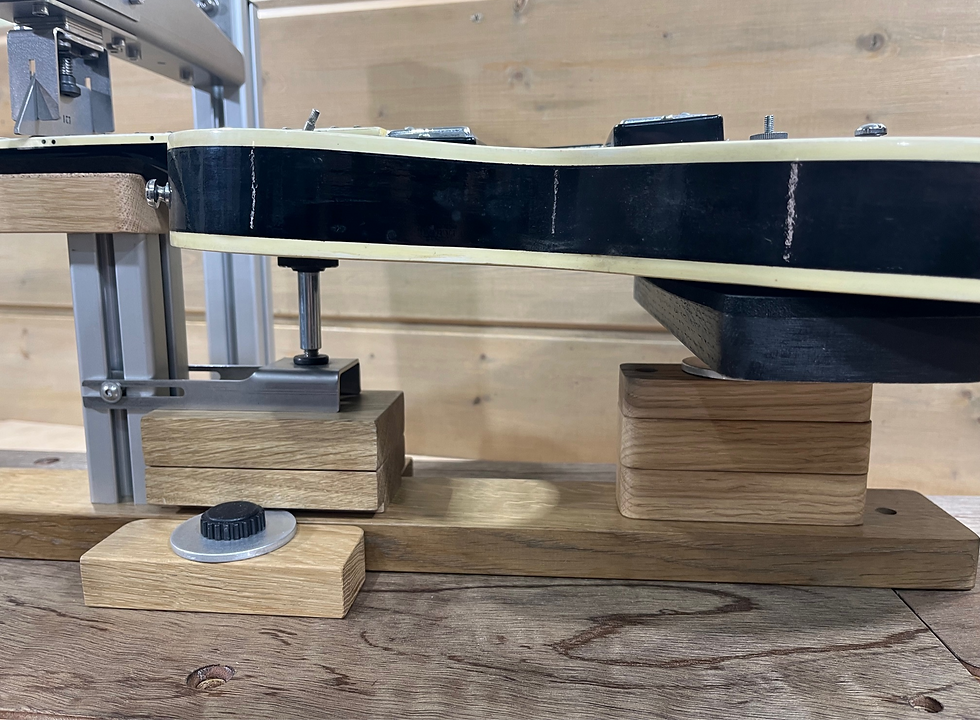

2) Guided Caul :- Constrained within parallel forks.

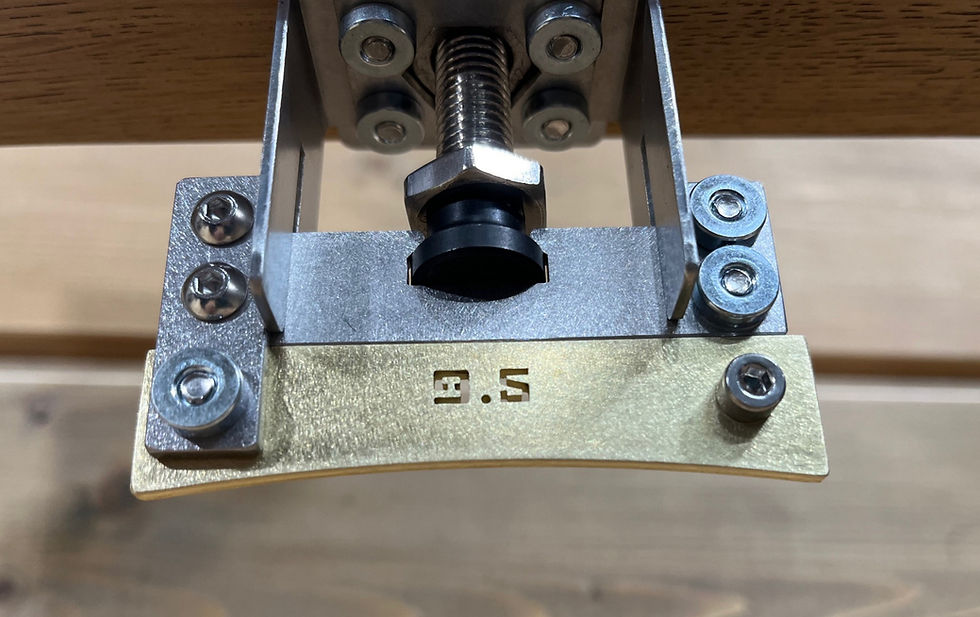

3) Radius Caul :- Centralises over the fret length for even pressure distribution.

TYPE OF CAUL

Choice of caul depends on individual preference although it is worth noting that a simple radiused caul allows for a small amount of misalignment whereas a grooved caul requires more precise alignment. To achieve the high quality and precision necessary, our grooved cauls are machined in house ensuring the radius is accurate and the groove is uniform along its length.

Q. Will the fretboard wood bend the fret into the right radius?.

A. No, the fretboard wood itself doesn't typically bend the fret into the desired radius. Fret bending tools or manual techniques should be used to pre-bend the frets to the correct radius before installation.

Q. Should the fret caul be the full length of the fret?.

A. Yes, a fret caul should ideally be the full length of the fret. This ensures even pressure distribution along the entire fret, preventing uneven seating and potential damage during installation. A full-length caul allows the pressure to be distributed evenly across the fret crown, resulting in a consistent and secure fret installation.

Q. Can a caul tip a fret over?.

A. Yes, a caul can potentially tip the fret over - if it isn't perfectly aligned, is over extended, or if excessive force is applied. Proper technique is crucial to avoid this issue. For optimum performance and stability a maximum of 10mm-15mm caul travel from the highest position is recommended. This will ensure that the caul is guided correctly in the forks as demonstrated below.